Mobile Apps

IoT Software Development: Revolutionizing Industrial Efficiency with Real-Time Machine Monitoring

A Fortune 100 corporation was looking to enhance their industrial machinery with real-time monitoring capabilities via an app and dashboard. This allowed to instantly view machine status and issues, broadening the client's offerings and elevating user experience.

Challenge: Driving Innovation with IoT Software Development

The growing global demand for industrial IoT solutions presented a significant challenge for a Fortune 100 manufacturer. The company had initially developed adapters that could read data from machine sensors and send it in a decoded format from CNC modules to computers within a local network for monitoring. However, as the need for advanced remote monitoring solutions became more pressing, the company realized they needed to upgrade these adapters with sophisticated software capable of supporting real-time, remote monitoring. To achieve this, the manufacturer sought a partner with expertise in IoT software development. They collaborated with Devvela to build a mobile application that would enable engineers to monitor machining tools in real time, regardless of their location.

Solution: Custom Software Development for IoT Monitoring

Given the diverse data formats produced by CNC machines, one of the primary challenges was ensuring uniformity of this data for remote monitoring. To address this, the adapter encoded the data into the MTConnect format using a specific XML schema, a standard in the industry. Devvela’s team developed applications capable of recognizing and processing this MTConnect data seamlessly.

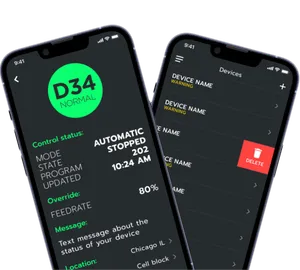

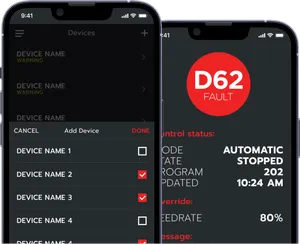

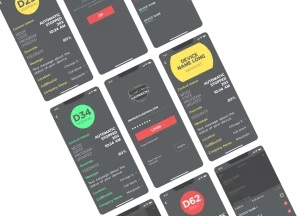

The mobile application we developed offered a user-friendly interface that allowed operators to monitor the operational state of machines in real time. The interface used a color-coded system to indicate the machine's status: green for “Normal,” yellow for “Warning,” and red for “Fault.” Additional parameters could also be monitored within the app, providing comprehensive insights into machine performance.

Understanding the operational needs of the client, we also included features that allowed managers to create lists of machines and assign them to specific operators. This customization enabled operators to filter and focus on the machines they were responsible for, enhancing efficiency. Additionally, to showcase the capabilities of the system at technology shows, Devvela built a web application that could display CNC information on a larger screen, such as a desktop computer or laptop.

Enabling Remote CNC Machine Monitoring for a Fortune 100 Manufacturer through Advanced IoT Software Development

Results: Success through Internet of Things Software Development

Working under tight deadlines, Devvela successfully delivered the product from scratch. The development of the mobile and web applications began in early summer 2018, and by September, the client showcased the product at the International Manufacturing Technology Show in Chicago.

The implementation of this custom software development for IoT allowed operators to monitor multiple CNC machines simultaneously, either from a smartphone or a PC. This increased efficiency, reducing the time spent on machine monitoring by 20%. Moreover, the system’s instant notifications on machine status changes enabled operators to act quickly on potential issues, preventing and reducing downtime.

Today, the client offers comprehensive CNC monitoring systems that include both the adapters and the mobile app developed by Devvela, highlighting the success of our internet of things software development services in enhancing industrial efficiency.